CUSTOM MADE

99% of our catalog is made up of original hoses generously entrusted by Clubs, Professionals and Individuals.

To design silicone hoses, there are several solutions that we explain below.

DIRECT FACTORY

Since our creation, we have worked with strict specifications entrusted to our contacts. Flexeo is in direct contact with the production managers at the factory, allowing for regular monitoring of the work undertaken. To date, 8 factories meet our requirements, allowing us to ensure manufacturing between 20 days and 1 month.

Comment procéder ?

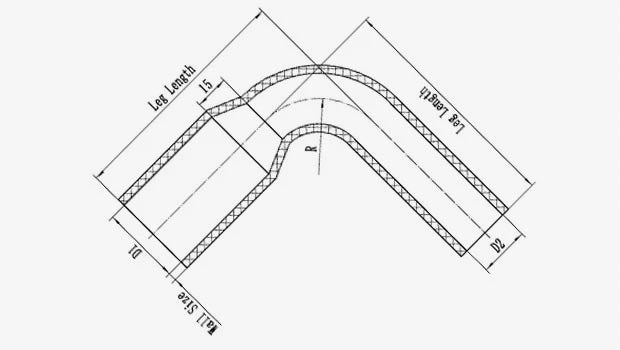

BY 2D / 3D DRAWING

We can start production from a 2D drawing. This process is used when the hoses to be remanufactured have one or more angles on the same axis.

Manufacturing lead time is improved as instructions are sent to the factory within 24 hours of quote acceptance.

PVC TEMPLATE

This is the most effective solution when it is impossible to entrust us with the original hoses, either because they are too worn, or to avoid immobilizing the vehicle.

Thanks to this PVC template, which is not forced to have the desired diameters, we are certain of the shapes to create; the angles, the distance between the crossing of the axes, etc.

ORIGINAL HOSES

Entrusting us with the original hoses is the best way for us to work on your project. Shapes, diameters, lengths and thicknesses are essential to reproduce the hoses identically. Sometimes, marks/cuts on the hoses can be the subject of a detailed study to improve the original design (avoid putting the hose in contact, reduce the thickness, etc.)

How to proceed?

Si la plupart des véhicules de collection rencontre une pénurie de durites avec le cahier des charges d'origine (nous insistons bien là-dessus), la refabrication de durites en silicone reste la meilleure alternative possible à ce jour.

En effet, les caoutchoucs d'époque avaient une durée de vie de 30 ans environ, ce qui est déjà énorme lorsque l'on compare avec les caoutchoucs d'aujourd'hui. La raison ? Les mélanges qui composent cet élastomère évoluent avec les normes, et pas dans le bon sens... n'avez-vous jamais entendu parlé de rongeurs qui s'attaquent aux durites caoutchoucs ? Lire l'article 60 Millions de consommateurs

Si le caoutchouc est apprécié pour conserver l'aspect d'origine de la mécanique pour les puristes, d'autres choisiront le silicone pour préserver leur mécanique. Le silicone, utilisé en compétition (sports mécaniques pro et amateur), puériculture (tétines de biberon), cuisine (moules à gâteaux, gants etc.) et maintenant chez certains constructeurs automobiles en première monte, dispose de caractéristiques hors pair pour résister aux températures et aux pressions les plus extrêmes (dans notre cas, pour l'automobile donc).

Tableau des témpératures

NITRILE: caoutchouc résistant aux hydrocarbures, huiles minérales et vapeurs huile.

EPDM: caoutchouc résistant au liquide de refroidissement

SILICONE: silicone résistant au liquide de refroidissement et circuit de suralimentation/air

FLUORO SILICONE: silicone résistant aux hydrocarbures, huiles minérales et vapeurs huile.

LE SILICONE : une pièce en silicone ne s'use pas, peu importe qu'elle soit stockée des années ou utilisée quotidiennement. Son aspect n'est pas 100% lisse en ce qui concerne les durites, mais le silicone mat permet d'avoir l'aspect le plus proche de l'origine en gardant toute l'efficacité du matériau. Le silicone est composé de tissus renforcé (nomex ou polyester)allant de 2 à 5 couches. Il résiste jusqu'à +230°C (contre 110°C pour le caoutchouc).Le prix est variable selon les vendeurs et nous nous efforçons de proposer le meilleur rapport qualité/prix possible. La durée de vie est infinie.